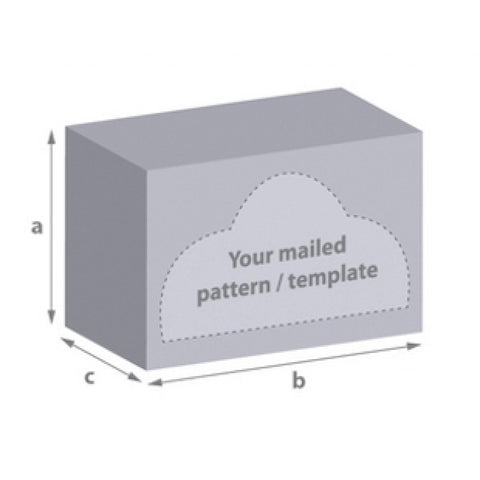

Firstly you will need to decide what you are going to use as a template.

Foam template options

- Wrapping paper

- Newspaper

- Wallpaper

- Cardboard

- Pattern (manilla) card

- Wood - Ply or mdf

Depending on the size of foam you might need to use sellotape to join newspaper etc to make it larger. It is common for the template to be required to match a wooden base.

Steps to make a foam template for a wooden base

- Place the chosen template material on a hard smooth surface. A table or hard floor are good options. Make sure the material has been laid out flat.

- Place the wooden base on top of the template material.

- Draw around the wooden base using a pen, pencil or marker pen.

- Using scissors cut the template.

Tip form our foam cutters: Foam is flexible and forgiving. It is better to go slightly oversized than undersized.

The above covers a basic template which can then be sent off to a company that cuts foam (hopefully us). Alternatively if you already have the foam then you can use the wooden base to draw directly onto the foam with a marker pen.

Alternative method to make a foam template

If the foam is going onto something that inst removable like a wooden board then it is likely fixed and going to be more difficult to template. Examples would be a fixed camper-van bed, pullout sofa mattress or boat mattress. We would suggest you do the following:

- Take a pen, tape measure, flexible pattern material and scissors.

- Start with the most difficult/awkward corner first.

- If you have a contour gauge then use it for the corners.

- If not you will need to use a combination of creasing your template where the edges are and oversized cutting. It is a good idea to use trial and error and cutting the template oversized at first. You can then refine your template by cutting/trimming more off the template material.

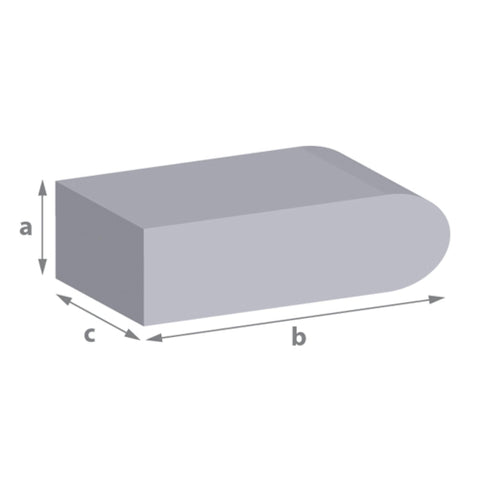

- Depending on the shape of the area you might need to measure multiple points using a tape measure and use dots to mark where the template needs to be cut. You can then either use a long ruler or something straight to join the dots. Curves would require freehand drawing - more dots will improve the accuracy.

Creating a template for a boat mattress

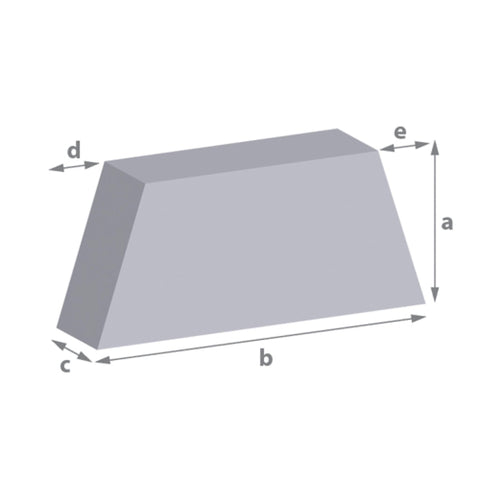

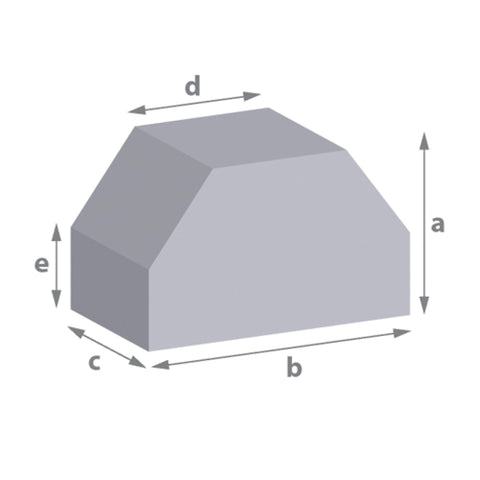

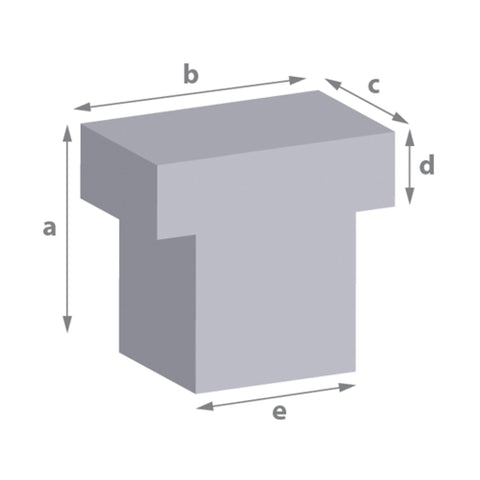

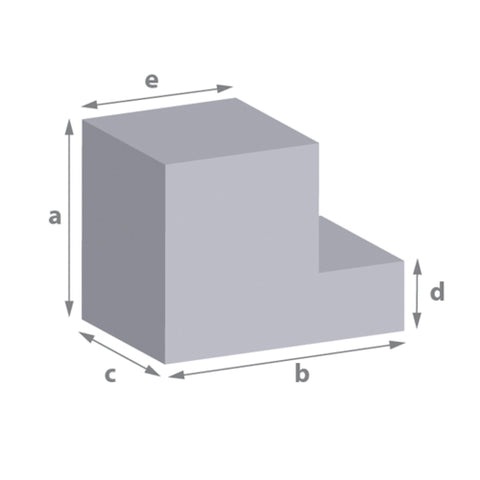

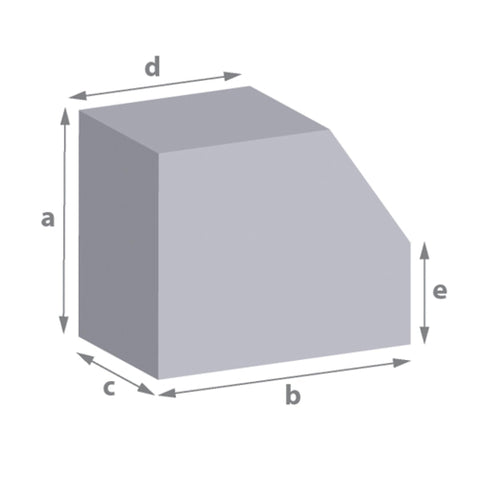

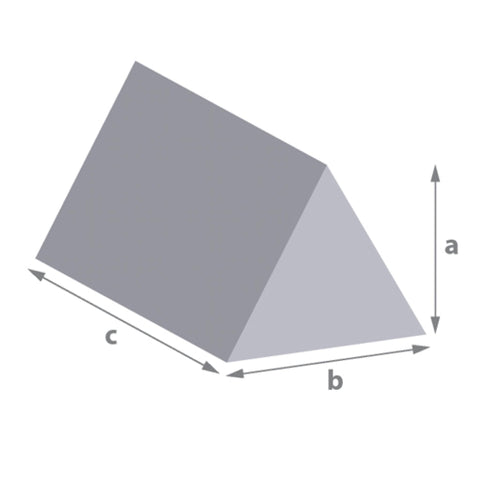

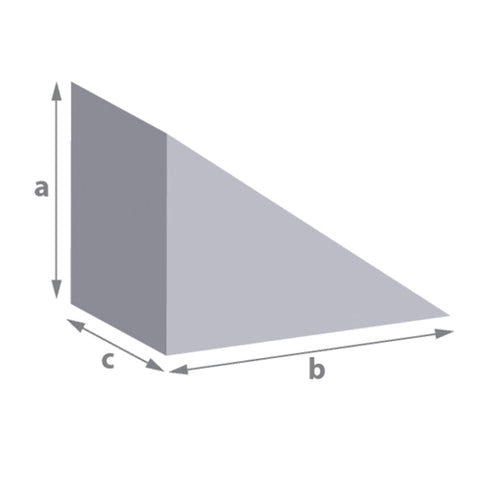

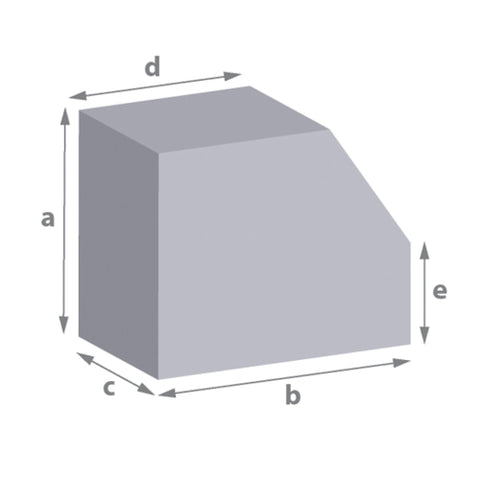

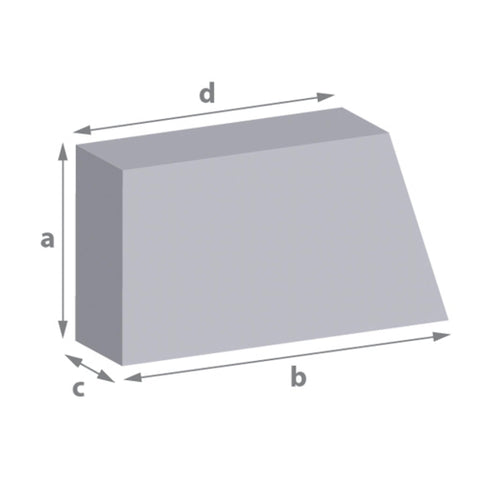

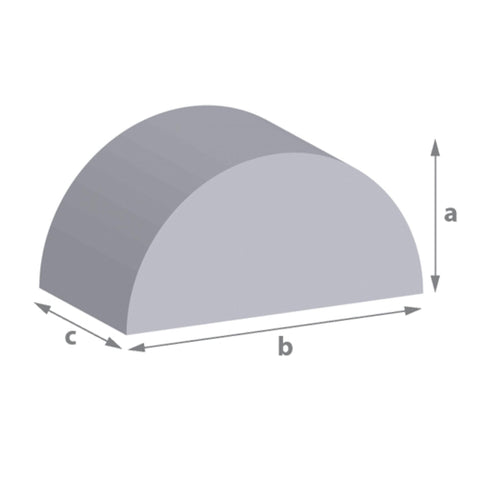

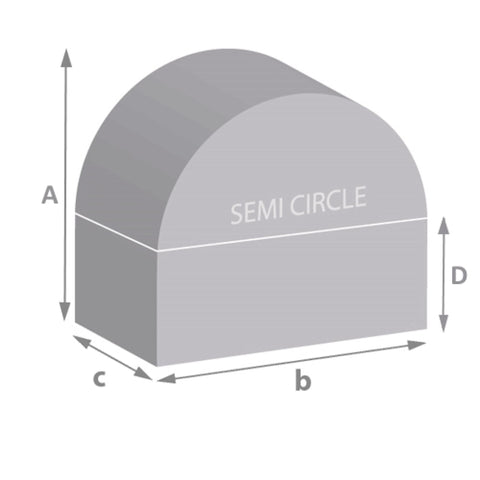

The easiest option is for foam cutters to receive the existing foam to replicate. If this is not possible you will need to produce a template. Depending on the shape of the berth and the shape of the hull you might need a bit of trial and error for corners. If the foam is going to have a chamfered edge then you will need to create two templates for one piece of foam. The top template will typically be larger for a boat mattress. You will need to mark on the template top and base. You will also need to make it clear to the foam cutters how the two templates align. You can do this by notching or marking both templates in 2 or more places at the same point. If all the sides are chamfered edges then you will need to either stick the two templates together in the middle or make two holes through both templates so that our foam cutters can lines these up when marking the foam.

If the base is removable wooden board (marine ply etc) then you can use the above steps. If not it is likely you will need to follow the 'alternative method' above.

Comments (0)

There are no comments for this article. Be the first one to leave a message!