We Cut Foam is proud to unveil the latest addition to its extensive product range, a material as innovative as it is versatile.

Say hello to reticulated foam, a cutting-edge solution designed to meet customer needs across multiple industries. Whether you are looking to enhance marine seating, craft outdoor furniture, or improve automotive interiors, reticulated foam delivers unparalleled performance.

This blog will explore what sets reticulated foam apart.

We’ll dig into its unique properties, many applications, and how it offers exceptional quality and sustainability. By the end, you’ll discover why reticulated foam is the material you didn’t know you needed for your next big project.

What Makes Reticulated Foam Unique?

At the heart of reticulated foam’s superiority lies its open-cell structure. Unlike conventional foam, reticulated foam undergoes a special manufacturing process where the cell walls are removed, leaving behind a lattice-like network. This structure provides phenomenal airflow, moisture resistance, and durability.

Here’s a closer look at its standout features:

1. Fast-Drying Capabilities

The open-cell structure allows water and moisture to pass through effortlessly, making reticulated foam one of the fastest-drying materials on the market. This property is especially valuable in environments such as marine applications and outdoor furniture, where exposure to water is inevitable.

2. Mould and Mildew Resistance

Thanks to its breathable design, reticulated foam discourages the accumulation of moisture, a primary cause of mould and mildew growth. This feature makes it ideal for humid or wet conditions, whether on a boat, in a garden, or even in a car.

3. High-Density Support

Despite its lightweight feel, reticulated foam offers high-density support. Its structural integrity ensures longevity, even in high-traffic areas like seating or industrial settings. You can compress it repeatedly without compromising its original shape.

4. Eco-Friendly and Sustainable

We Cut Foam prioritises sustainability in all its offerings, and reticulated foam is no exception. It’s durable and long-lasting, reducing the need for frequent replacements and lowering your environmental footprint.

5. Customisation Versatility

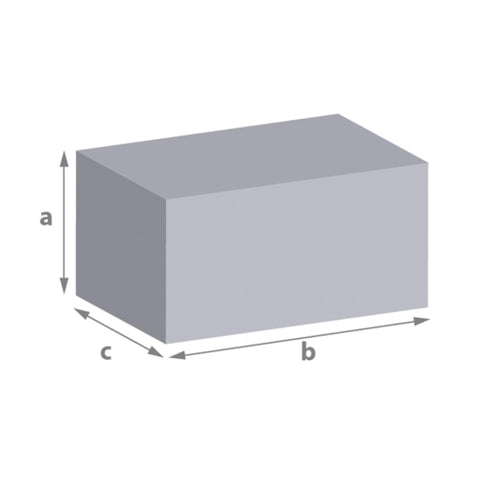

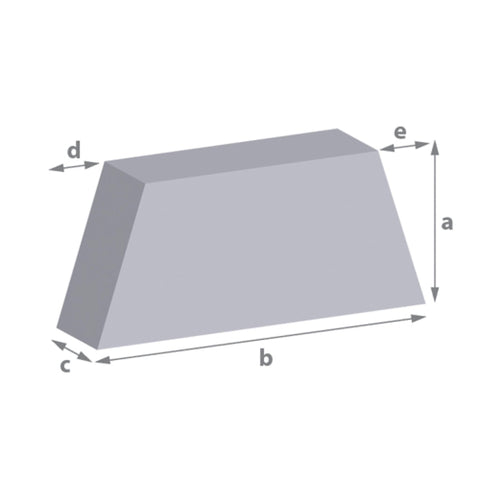

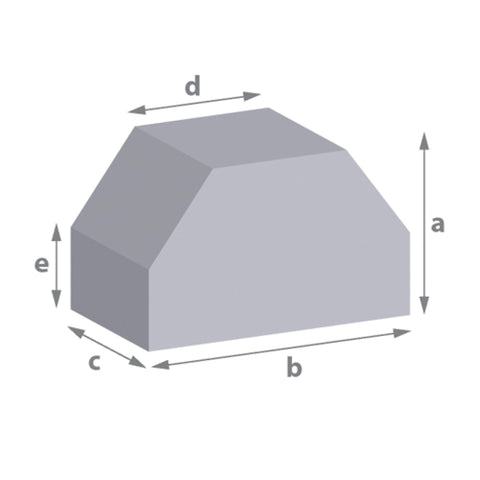

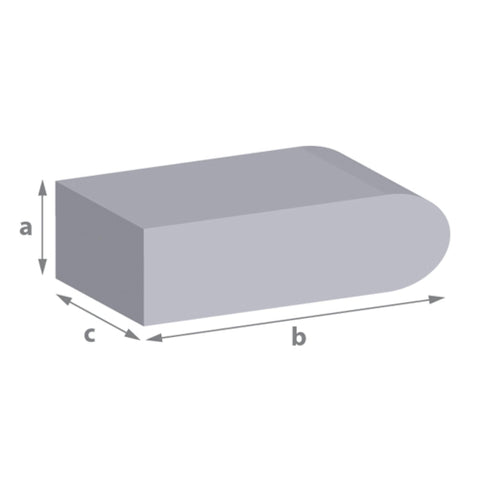

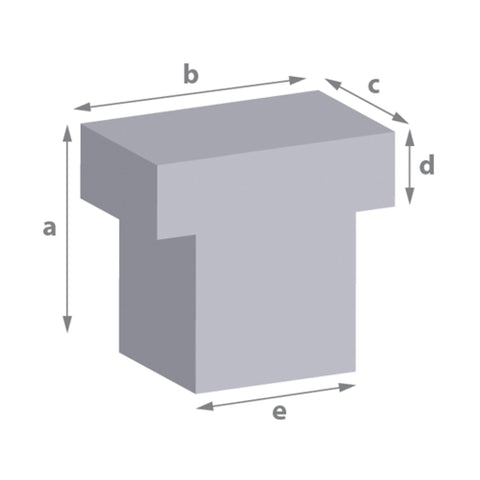

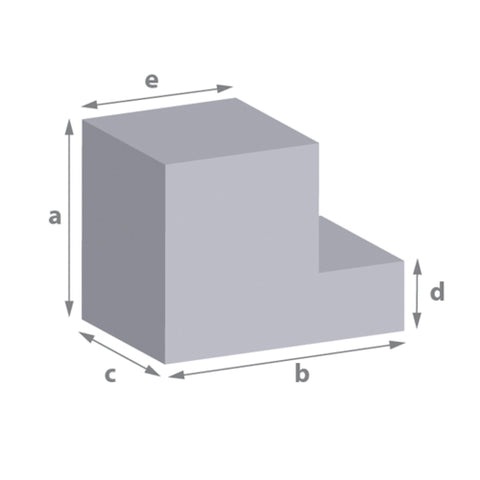

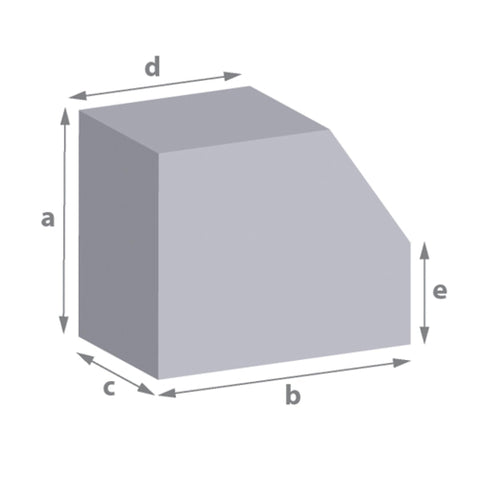

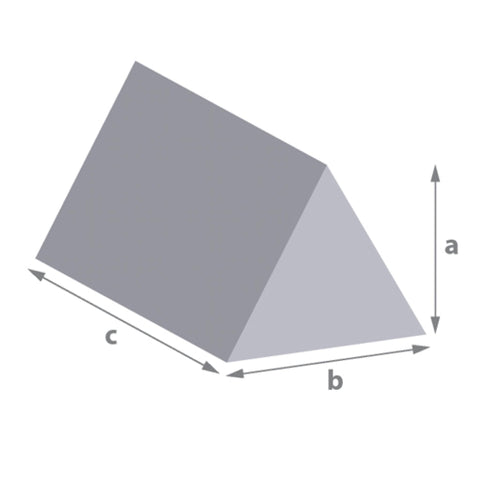

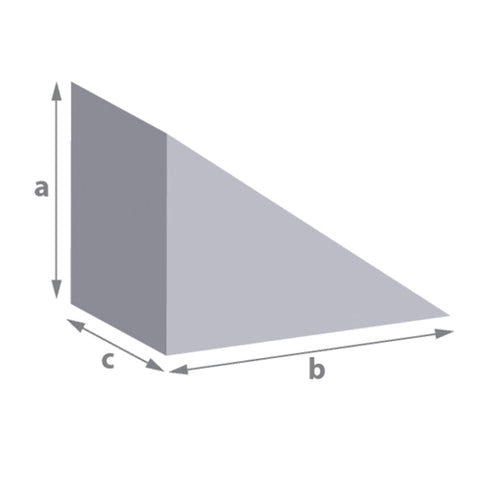

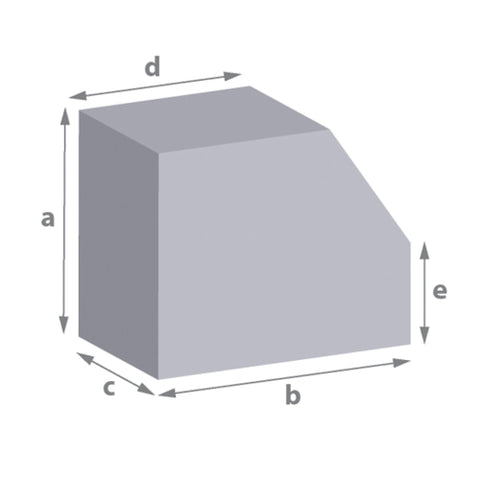

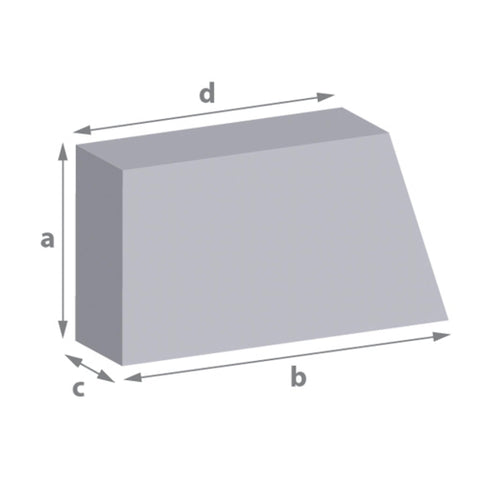

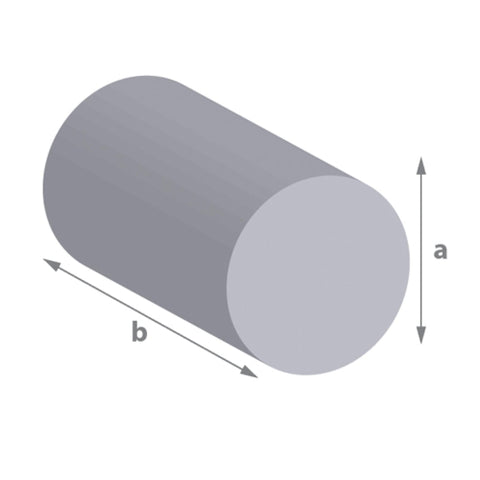

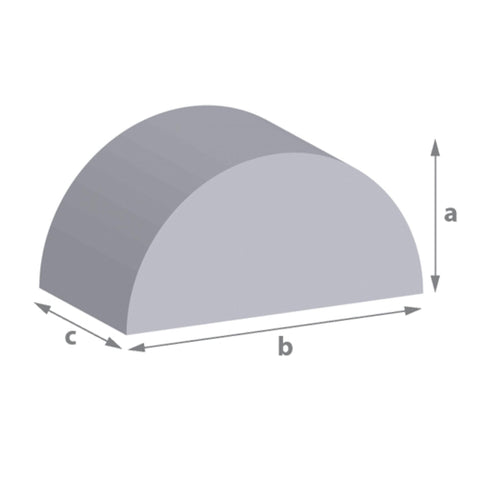

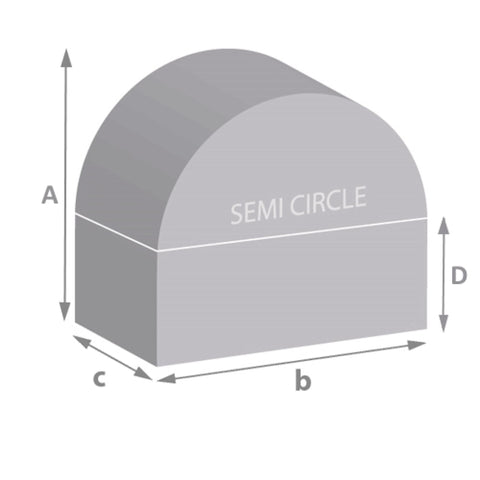

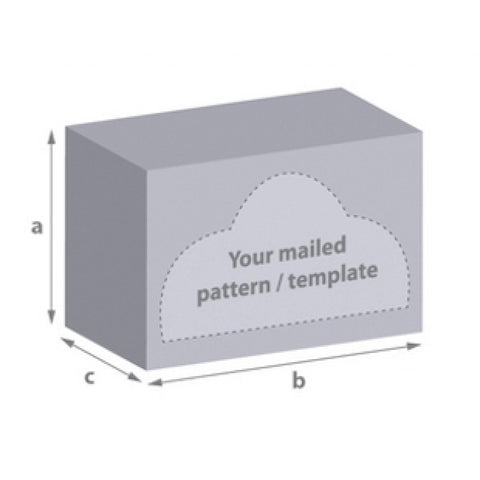

Reticulated foam can be easily cut to size, tailored to the exact specifications of your project. This versatility ensures you always get a product that fits perfectly.

See also - 10 Creative Applications for Custom-Cut Foam in Your Home

Applications Across Industries

Reticulated foam isn’t just a one-trick pony.

Its remarkable properties make it suitable for diverse industries, from marine and automotive to outdoor design. Here’s how it shines in real-world applications:

1. Marine Industry

Life on the water demands materials that can endure constant exposure to moisture and salt. Reticulated foam is the ideal solution for boat seating, cushions, and mattresses. Its fast-drying capabilities make it an excellent choice for keeping surfaces comfortable and free of water damage, while its resistance to mould ensures it stays fresh over time.

Example Use: Imagine a yacht owner's delight as their deck cushions remain dry and pristine, even after a rainy day or water splashing aboard. Custom shapes ensure these cushions fit bespoke seating perfectly.

2. Outdoor Furniture

When it comes to outdoor furniture, durability is key. Reticulated foam provides the perfect balance of comfort and toughness. Its lightweight yet robust structure resists degradation from moisture, mould, and UV exposure. Its ability to retain shape under consistent use also guarantees longer-lasting comfort.

See also - Transform Your Outdoor Spaces with Custom Foam for Furniture and Tree Seats

Example Use: Picture a garden seating solution where cushions always feel luxurious, even after an unexpected downpour. Simply shake out any water, and the foam will dry in no time.

3. Automotive Applications

The automotive industry benefits greatly from materials that provide high support and moisture resistance. Reticulated foam is a go-to choice for car seat padding, headrests, and soundproofing. Its resistance to chemicals and petroleum-based products adds another layer of practicality.

Example Use: Consider how classic car restoration enthusiasts can revamp seat interiors with durable, breathable foam that stands up to wear while looking sleek.

See also - Everything You Need to Know About Fire-Safe Foam for Motorhomes and Caravans

4. HVAC Filtration Systems

The porous structure of reticulated foam allows it to function as an efficient filtration material. It works wonders in trapping dust, dirt, and other particles, making it an essential component in air conditioners, furnaces, and vacuum systems.

Example Use: A technician can rely on reticulated foam for HVAC filters that ensure clean air and high energy efficiency at the same time.

5. Sports and Lifestyle Equipment

From athletic padding to flotation devices, reticulated foam proves its versatility in the sports industry. Its high tensile strength and resistance to tearing guarantee reliable performance across rigorous applications.

Example Use: Visualise a high-quality yoga bolster that maintains its firmness and hygiene thanks to reticulated foam’s tensile properties and moisture resistance.

See also - From Canal Boats to Yachts: The Ultimate Guide to Custom Cut Foam on the High Seas!

Why Choose Reticulated Foam for Your Projects?

If you’re still wondering whether reticulated foam suits your needs, here’s a recap of why it’s a smart investment:

- Unmatched Durability: Its strength and resilience ensure it can be used repeatedly without losing its form or integrity.

- Comfort Guaranteed: Experience optimal support whether you're crafting furniture, cushions, or mattresses.

- Customisation Flexibility: Available in various thicknesses and densities, reticulated foam can be tailored to your specifications.

- Low Maintenance: Easy to clean and resistant to water damage, making it simple to care for over time.

- Sustainability: Its long lifecycle minimises waste, reducing environmental impact.

Whether you’re designing outdoor furniture for a chic patio set or looking for an upgrade in automotive seating, reticulated foam delivers on all fronts.

See also - Custom Comfort for Your Travels: Campervan & Caravan Mattresses and Toppers

How Can You Incorporate Reticulated Foam?

We Cut Foam offers a free cutting service, so you can simply send in your dimensions and get foam that’s the ideal size and shape for your specific project. The team can even replicate old cushions if you send them in, ensuring a perfect match every time.

Here are just a few ways customers have already started using reticulated foam in their projects:

- Decking out Campervans for the ultimate road trip comfort.

- Upgrading Poolside Loungers with fast-drying, mould-resistant cushions.

- Designing commercial seating for cafés and other high-traffic arenas.

With the ability to transform spaces into functional and comfortable areas, reticulated foam isn’t just a product; it’s a solution.

See also - Enhancing Wellness and Spa Spaces with Custom Cut Foam

The Future of Foam Is Here

The arrival of reticulated foam at We Cut Foam represents a leap forward in material technology. Its enduring properties, wide-ranging applications, and focus on sustainability make it a top contender for industry professionals and DIY enthusiasts alike.

Whether you need foam that stands up to the rigours of marine life, handles outdoor weather challenges, or brings comfort and durability to high-traffic spaces, reticulated foam is the perfect choice.

Get in touch with We Cut Foam today to learn more about this innovative product or to place a custom order.

It’s time to bring your projects to life with the power of reticulated foam.

Comments (0)

There are no comments for this article. Be the first one to leave a message!