If you’re exploring options for durable and versatile foam solutions, reticulated foam is one material you’ll want to know about. Whether you’re dealing with outdoor seating, marine upholstery, or even custom-shaped mattresses, this unique foam offers plenty of advantages. But what exactly sets reticulated foam apart, and how can it meet your specific needs?

This blog answers the most commonly asked questions about reticulated foam while explaining how We Cut Foam can provide tailored solutions to match your requirements.

What is Reticulated Foam?

Reticulated foam is a specially processed type of polyurethane foam characterised by its open-cell structure. Unlike traditional foams, which have a mixture of closed and open cells, reticulated foam has most of its membranes removed, leaving behind an interconnected network of cells.

This unique structural feature allows:

- Enhanced water drainage: Water flows easily through the foam, making it ideal for environments prone to getting wet.

- Improved airflow: The open structure promotes ventilation, keeping surfaces cool and comfortable.

- Lightweight yet strong design: Reticulated foam is both sturdy and flexible, perfect for long-lasting support.

We Cut Foam’s reticulated foam sheets are available in custom sizes, ensuring they meet your specific needs down to the millimetre.

Why is Reticulated Foam Fast-Drying?

One of the most renowned features of reticulated foam is its fast-drying properties. Thanks to its open-cell structure, water doesn’t collect within the foam but instead flows right through it. This makes it a superior choice for applications in humid or wet environments, such as:

- Boat cushions: Constant exposure to water can lead to soggy, bacteria-prone cushions. Reticulated foam ensures rapid drying and prevents waterlogging.

- Poolside seating: Sun loungers and cushions made with reticulated foam can handle splashes from the pool without becoming heavy or misshapen.

- Outdoor furniture: Even in the rain, reticulated foam cushions stay functional because they dry quickly once exposed to air.

A Handy Tip:

To maintain the foam’s fast-drying capacity, you can occasionally rinse it with fresh water to remove any debris or salt when used in marine environments.

See also - Introducing Reticulated Foam: A Game-Changer in Foam Technology

What is PPI, and Why Does it Matter?

PPI, or Pores Per Inch, measures the density of cells (or pores) in reticulated foam. Understanding PPI is essential when selecting foam for a specific purpose:

- Low PPI (20-30): Larger pores ensure better airflow and faster water drainage. This range is ideal for outdoor seating and marine cushions.

- High PPI (50+): Smaller pores offer more refined filtration properties and are often used in applications like air filters or fine liquid sieves.

We Cut Foam provides reticulated foam options with a PPI of 25, which strikes the perfect balance between durability, drainage, and comfort. This makes it particularly suitable for boat cushions, outdoor seating, and other high-humidity uses.

What Makes Reticulated Foam Mould-Resistant?

Moisture is the primary trigger for mould and mildew, especially in foams used in wet conditions. However, reticulated foam’s unique design allows water to flow through without becoming trapped. Additionally, its dense yet open structure promotes faster drying and airflow, further discouraging mould growth.

Ideal Applications:

- Marine cushions and mattresses: Reticulated foam's mould-resistant qualities are indispensable in yachts, fishing boats, and houseboats where moisture exposure is constant.

- Garden furniture: Say goodbye to worrying about cushions retaining water and developing a musty smell over time.

Why is Reticulated Foam Perfect for Outdoor Use?

From patios to sandy shores, outdoor environments are demanding spaces for cushions and seating.

Reticulated foam excels here because of:

- Durability under harsh weather: Sun and rain cycles, coupled with high humidity, can deteriorate regular foam quickly. Reticulated foam holds its shape and performance, season after season.

- Cool comfort in hot climates: Thanks to its breathable design, it reduces trapped heat, offering a more comfortable experience during prolonged use.

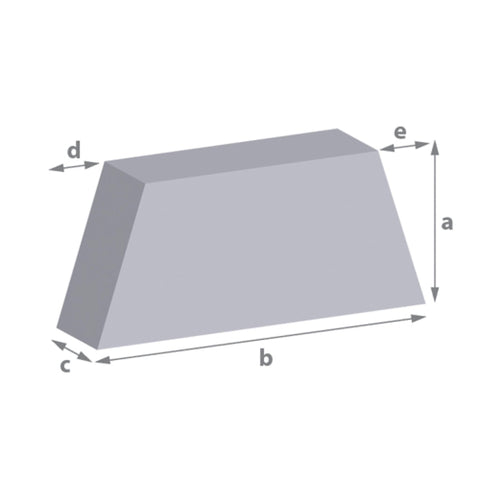

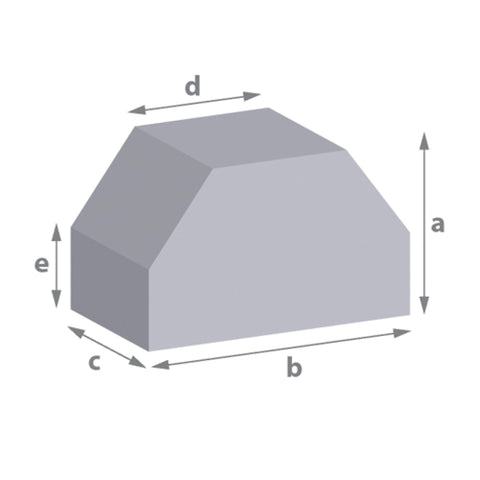

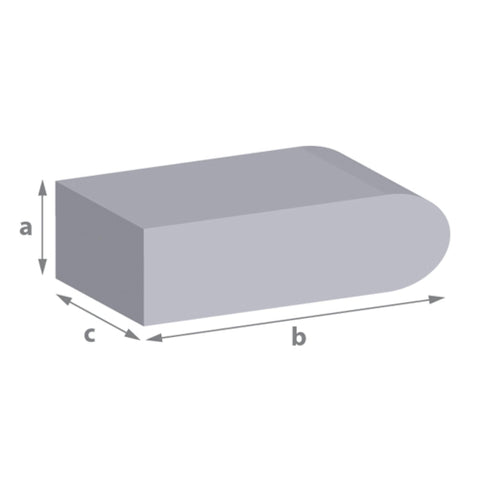

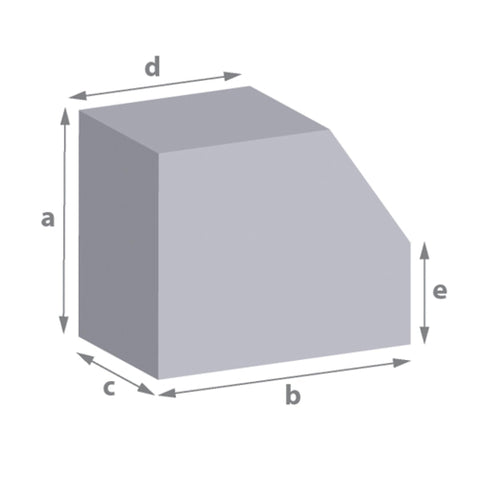

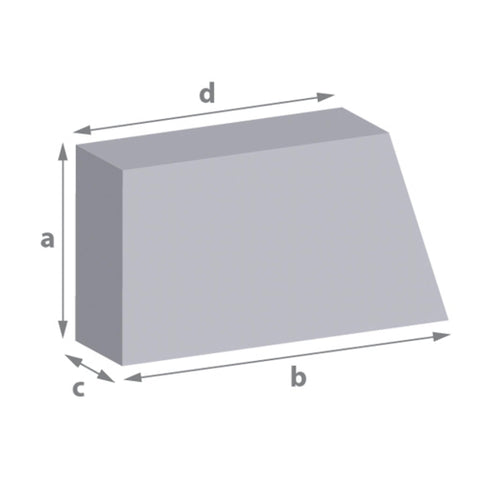

At We Cut Foam, we cut reticulated foam pieces to your exact specifications and can even replicate existing cushion shapes or offer chamfered edges for bespoke designs.

How Does Reticulated Foam Compare with Traditional Foam?

Traditional foam options, while economical, tend to fall short in demanding applications.

Here’s a quick comparison:

|

Feature |

Reticulated Foam |

Traditional Foam |

|---|---|---|

|

Water Resistance |

Excellent (fast-draining) |

Poor (water-trapping) |

|

Airflow |

High |

Limited |

|

Durability in Wet Environments |

Outstanding |

Prone to mold/mildew |

|

Customisation Options |

Extensive (varied thickness & PPI) |

Limited |

For instance, if you’re furnishing the deck of a sailboat, a reticulated foam cushion would outperform traditional foam, ensuring both durability and comfort over time.

See also - Best Foam for Boat Cushions: What the Pros Use the Ultimate Guide

How Can I Customise Reticulated Foam?

One common query is the extent to which reticulated foam can be customised.

At We Cut Foam, we pride ourselves on our free cutting services, tailored to your exact needs.

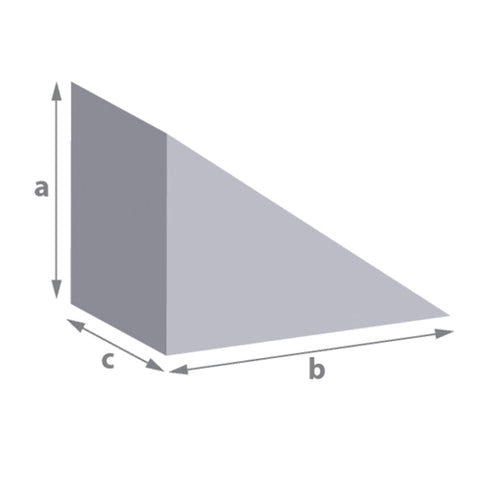

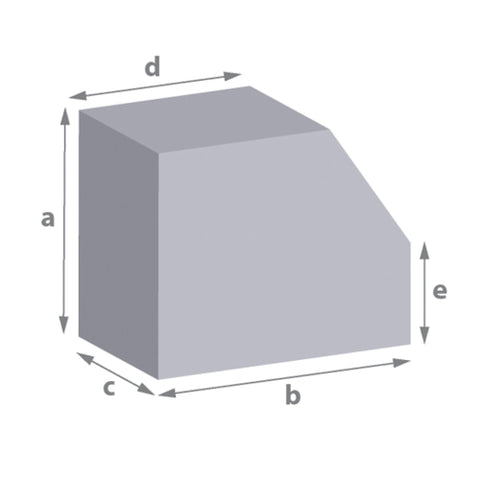

Here are some ways you can personalise your foam:

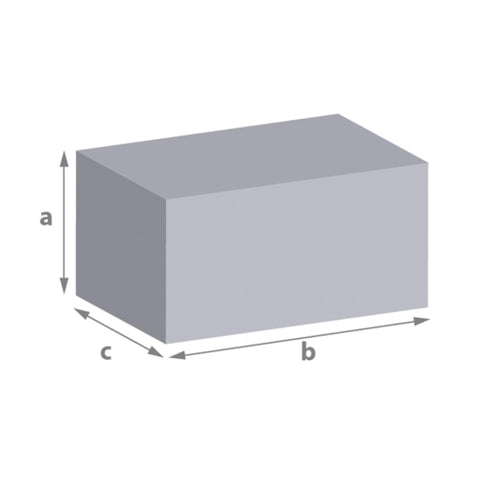

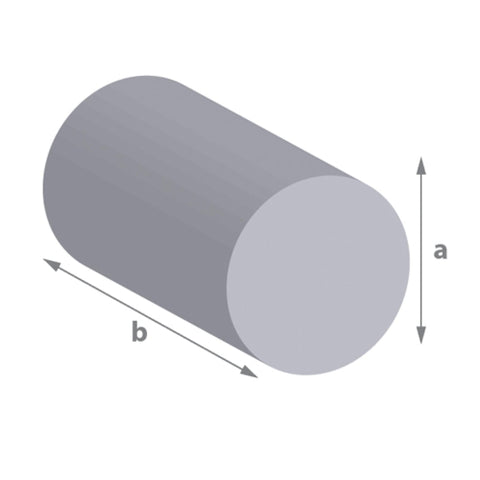

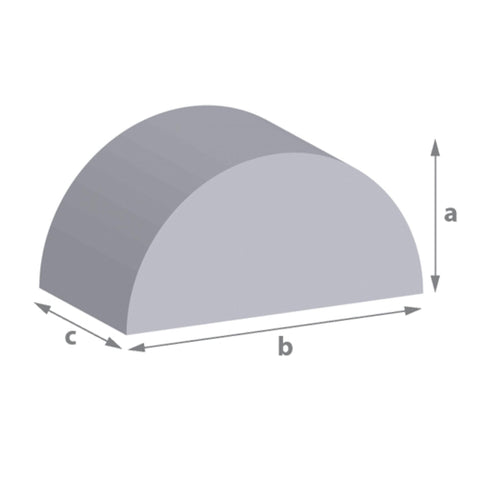

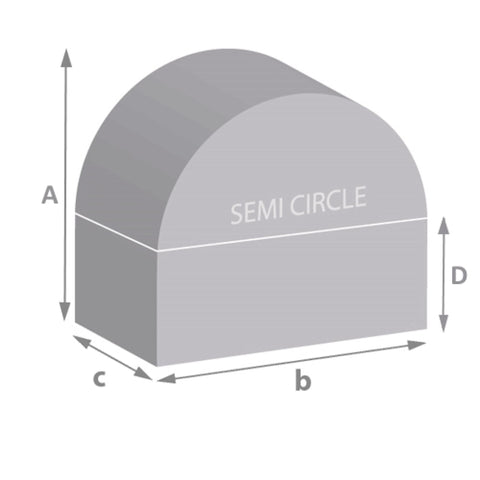

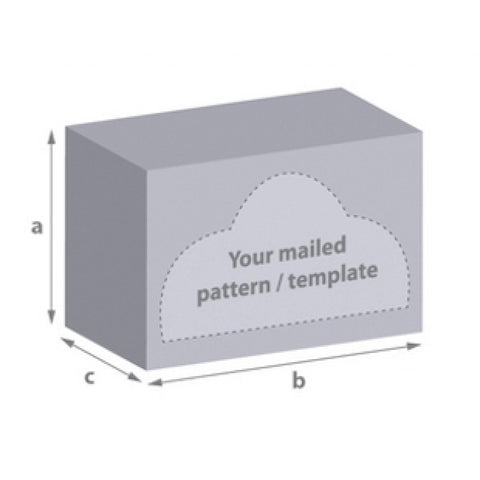

- Thickness: From as thin as 1 inch up to thicker blocks for maximum support.

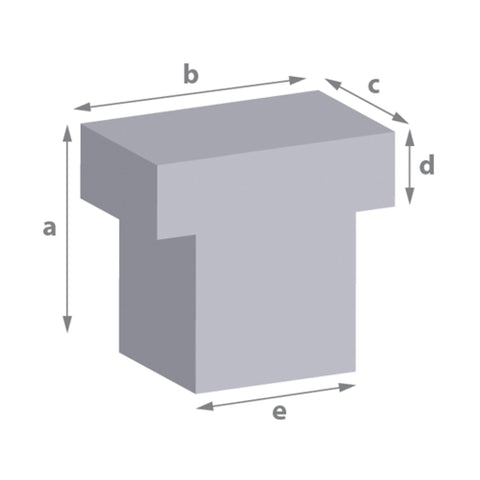

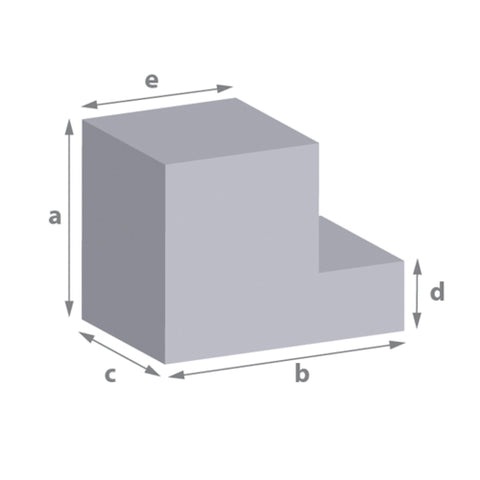

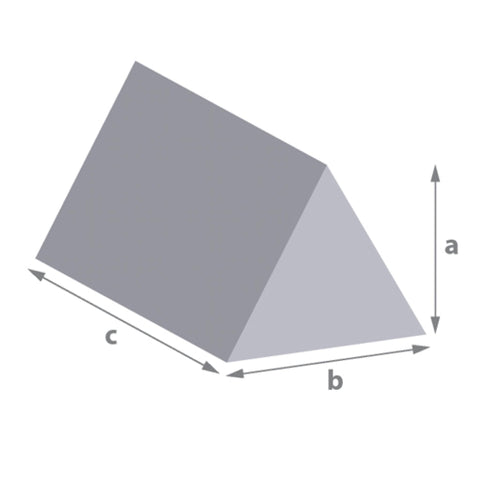

- Shape: Anything from standard squares to niche shapes like triangles, T-cushions, or bolsters.

- Complex Profiles: If you need foam for irregularly shaped objects, such as camper van seating, we can replicate existing templates or shapes.

- Applications: Beyond seating and mattresses, our foam can be modified for soundproofing or aesthetic purposes.

Is Reticulated Foam Fire Retardant?

Yes!

At We Cut Foam, safety matters. Reticulated foam we supply meets UK fire safety standards, including BS 5852 (British Fire Standard) as well as IMO Part 8 regulations for marine use.

This fire-safe certification ensures that our foam is suitable not only for private applications but also for commercial settings, such as hotels and public spaces.

Why Choose We Cut Foam for Reticulated Foam?

With years of experience in crafting and supplying foam solutions, We Cut Foam distinguishes itself through:

- Quality Assurance: We use high-grade reticulated foam that balances durability with comfort.

- Tailored Solutions: Thanks to our expertise in custom cutting, you can count on foam pieces that perfectly match your specific needs.

- Compliance and Certification: All our upholstery foam meets or exceeds the required UK fire safety standards for peace of mind.

- Convenience: You can easily upload templates or specify dimensions, and we’ll deliver the foam directly to your door.

A Perfect Fit, Every Time - The custom cuts were spot on. This foam arrived quickly and was ready to use right away. - Thomas E

Retiuclated Foam - No more FOMO

Reticulated foam is a game-changer for anyone needing durable, breathable, and water-resistant material for outdoor or marine applications. When combined with expert customisation and certified fire safety, it serves as the gold standard for seats, mattresses, and cushions.

When you’re ready, trust We Cut Foam to deliver exactly what you need, whether you’re re-covering yacht seats or fashioning bespoke garden furniture.

Explore our range of custom cutting services today to see how we can bring your foam project to life!

Comments (0)

There are no comments for this article. Be the first one to leave a message!